How are electric coil stoves made? Electric coil stoves are great at maintaining low heat and the key to maintaining an electric coil stove is understanding how it is made. Electric coil stoves are also known as the electric range and this is a stove with an integrated electrical heating device to cook and bake, this sleek and trendy coil plate is the most popular form of stoves in many households and this can save you the risk and expense of using gas stoves.

Electric coil stoves don’t produce flame, unlike gas stoves, instead, an electric current causes a heating element to activate and if your stoves have coils, then the heat is transferred directly from these coils to your cookware. Knowing the internal functions of an electric coil and how it works makes you feel more comfortable when using it.

When you are in the market for a new range, it can be tough making a voice between a smooth and coil top electric range as the two are quite efficient in the kitchen. There are lot’s of benefits to having an electric coil stove, it works best in any kind of kitchen while meeting your needs and preference and below is how it is made to help understand how to operate and maintain it.

Table of Contents

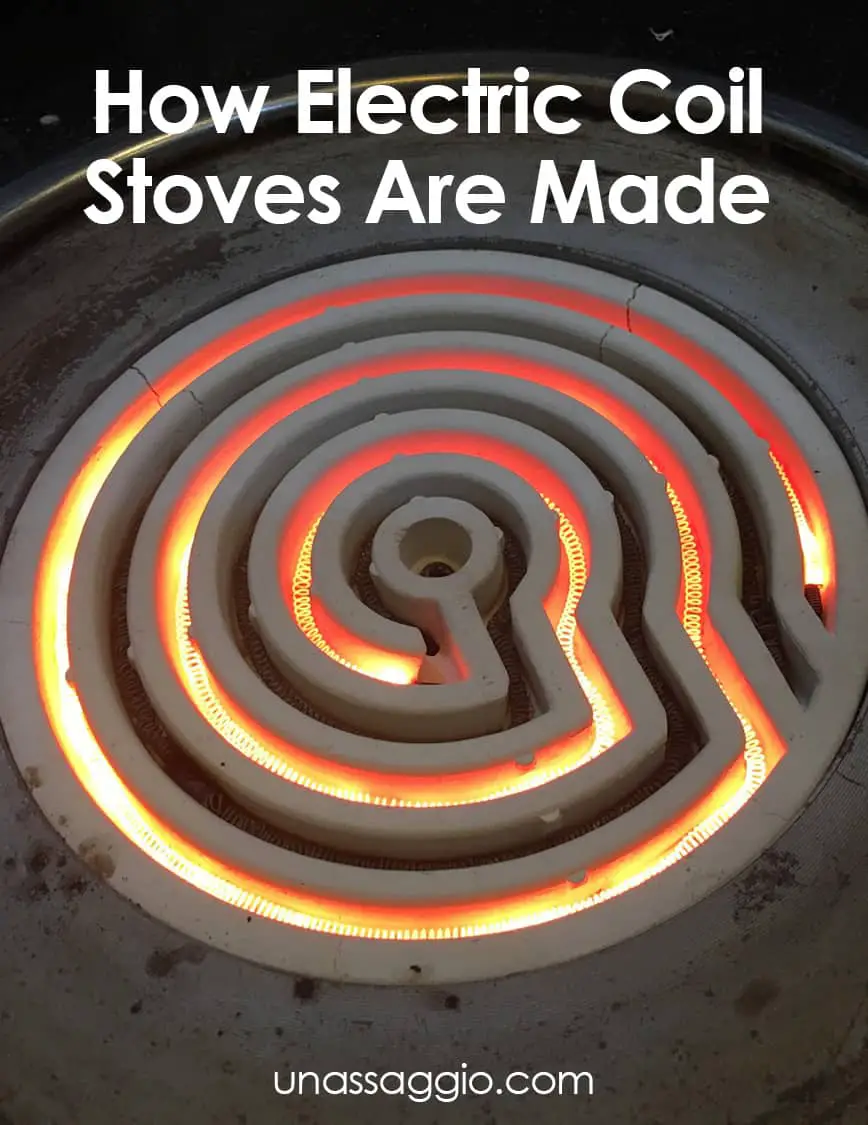

How Electric Coil Stoves Are Made

Electric coil stoves are appliances made from metal alloys which comprise of two or more elements. Electric burner has two types of a coil which are the conventional coil and the radiant coil. Each is controlled by a switch and can be operated by using a 240 VAC with 2 legs of voltage each carrying 120 voltage.

When the selected knob is turned to your preferred heat server, the first leg of voltage travels to one side of the hidden element and the second leg of voltage travels to the opposite side when the voltage reaches the hidden elements, the socket is closed and the element begins to heat up. The switch regulates the hidden element when the element reaches the designated temperature, the switch shuts off the voltage.

Electric coils can be made from some materials such as Nichrome, alloys of nickel, iron, chrome and so on. Nichrome is most used by manufacturers because it combines both nickel and chromium and because of the flexibility of their wires. Nichrome’s alloy also possesses a high melting point.

An electric coil also contains other compounds such as alloys of nickel, iron, and chromium. The two coil element ( conventional and radiant coil ) are made of tungsten and stainless steel that requires a higher temperature.

The problem with electric stove top includes elements not heating, heating intermittently or element overheating. If one the element is not heating up properly, you should test the continuity of the wires to determine if the continuity of the electrical part is present, if the element has continuity it is likely that the switch is affected and will need to be replaced.

Some electric coil requires insulation materials such as fibreglass, ceramics and synthetic materials are used with mica and asbestos. Thick wire is used to generate a high current of electricity so make sure you wrap up your wire with a conductor material.

Is an electric stove better than gas?

No, while it may be easier to save energy on an electric stove, a gas stove might still be a winner as it is cheaper to operate gas stoves for your needs and although electric stove tends to save energy compare to gas. Electric stove sometimes gets heated faster than gas stove but the level of heat can be controlled more quickly and easily with a gas stove by simply turning the flame up or down however seventy-four per cent of the energy produced by the electric stove is transferred to food while gas stove operates on 40 per cent range.

Are coil stoves good?

Yes, coil stoves are great kitchen cookware to have in any home, it can handle nearly any pan or pot you put on them and this is because your pan sits directly on them and the metal conducts heat well. Coil stoves are efficient and are easily replaceable if they are damaged or no longer sit level. Coil stoves typically have drip pans underneath the coil drips which catches spills.

Can you use cast iron on an electric coil stove?

Yes, a cast iron can be used on an electric coil stove as it’s really versatile hence you can use it to cook on a gas stove as well as an electric coil stove. When using cast iron on an electric stove coil, it is recommended to lower the heat to avoid creating hot spots and burning your food. Cast iron pans can also be used in ovens or campfire and it’s multipurpose cookware to have fir every modern chef.